How to remove sparks from a chimney. Do-it-yourself spark arrester on the chimney, photo

We welcome regular and new readers of our review cycles! When using fire indoors, special attention should always be paid to the risks associated with it. In particular, we are talking about fires that can be caused by the operation of solid fuel boilers or a fireplace. One of the effective measures against such force majeure is a spark arrestor on the chimney. Today we will analyze in detail what this device is, as well as issues of self-assembly and installation.

The spark arrestor is designed to extinguish sparks flying out of the chimney when fuel is burned in the stove / fireplace.

Usually it is mounted directly on the chimney of the bath or a special glass for attaching deflectors. Such an installation is a special nozzle with a metal mesh cylinder and a protective visor at the top.

Spark arrester device

The structure and principle of operation of this device are clear and extremely simple. Depending on the model, it may differ in appearance and structure. But the basis of any such modification is always four elements:

- a net that catches flying sparks and extinguishes them;

- element for extinguishing the flame;

- visor in the form of a cone on top.

Principle of operation

The principle of operation is to limit the free movement of sparks flying out of the chimney. The special design repeatedly redirects the movement of particles that stumble upon various obstacles.

Upon impact with a metal mesh with the smallest cells, the sparks break, the speed of their movement decreases along with a change in direction of movement. Upon subsequent collision with a metal structure obstacle, the particles are extinguished without leaving the chimney.

These obstacles-filters do not interfere with the free movement of gas.

Kinds

There are many types of such units. They differ in shape, size and the very element responsible for extinguishing the spark.

Structurally, these devices can also differ. As part of individual heating, spark arresters of the following types are most often used:

- spark arrester-casing;

- spark arrester-deflector.

Advantages and disadvantages

Speaking about the advantages common to all designs, it is worth noting the unhindered exit of smoke from the pipeline and. In the case of spark eliminators-deflectors, the thrust indicator increases.

The option in the form of a casing or a mesh cap is characterized by the simplest and cheapest assembly scheme, as well as the simplest installation.

There are some shortcomings here. For example, this variety is devoid of a deflector umbrella that prevents precipitation from entering the chimney. The second drawback of such a spark arrester is the absence of a partition that changes the movement of gases along the axis.

Life time

The service life directly depends on the quality and type of metal used. Ferrous metal, provided it is used in intensive mode (individual heating), will allow the spark arrester-deflector to last 5-7 years.

Alloy steel has a service life of 10 to 20 years.

This indicator is also significantly affected by the intensity and frequency of use of the heating boiler.

Do it yourself or order the device?

Custom spark arresters are a fairly common option. If you trust the contractor, you can count on a good service life and full serviceability. But this is not always the case, especially if the manufacturer decides to save on material.

If you decide to make the spark arrester yourself, it may take you longer. At the same time, you will be able to fully control the process, starting with the selection and acquisition of material, and ending with the design nuances.

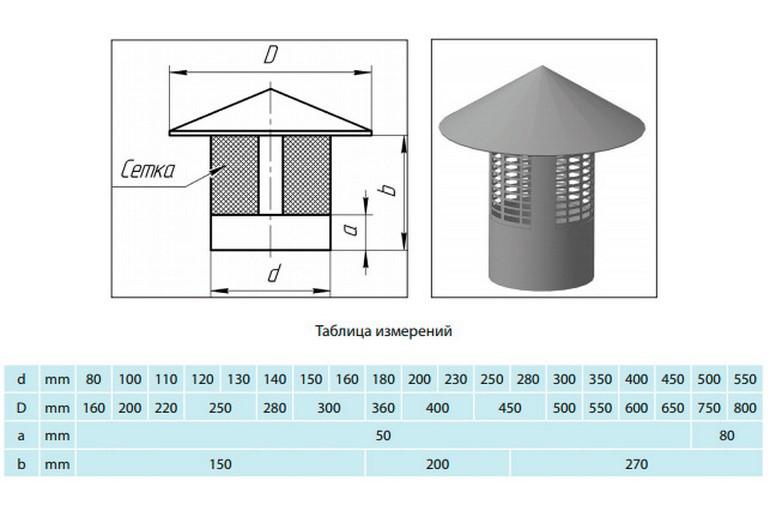

When choosing, you should pay attention to the dimensions of the pipeline, the type of construction and the quality of the material. The diameter of the devices, as a rule, is 80-550 mm. The dimensions of the visors depend on the dimensions of the tubular structures that are put on the chimney.

Popular Models

There are simplified shell-shaped versions and solutions with a deflector function. Among the latter, the following popular modifications can be distinguished:

- TsAGI;

- Grigorovich's apparatus.

- Round Volper.

- H-shaped device.

- Vane.

- Poppet.

Do-it-yourself step-by-step manufacturing and installation of a spark arrester

Let's consider a step-by-step manufacturing option for a spark arrester, consisting of a body, a mesh structure and a deflector cap.

Necessary materials and tools

For self-assembly of such a spark arrester, you will need the following tools:

- measuring instruments (tape measure, level, etc.);

- screwdriver, clamps, pliers and hammer;

- rivets in a set or a welding machine;

- metal scissors, grinder, drill and drill bits.

Consumables are selected purely individually depending on the type of device.

Drawing and diagrams

Here is an example of assembling a simple spark arrester based on a common basic drawing.

Let's designate the main components and along the way we will tell you how to make them:

- Cylindrical branch pipe - a glass that will be put on the chimney pipe. For the manufacture you need a metal sheet. We cut out a rectangle from it with a length equal to the length of the circle lying at the base (Fig. 2).

You can calculate the required dimensions using the formula: "L \u003d π × D", where L is the length, π ≈ 3.14, and D is the desired cylinder diameter. We carefully bend the resulting strip with a pipe, for example, into a cone, combine the edges, drill several holes on them and fasten them with rivets.

- Metal mesh - a network with cells. It is best to purchase a ready-made stainless steel mesh base. A cylinder based on it is made in the same way as a glass.

- Protective umbrella cap - the main thing here is to correctly pattern the cone. To do this, we calculate the required workpiece radius using the formula: “C \u003d √ (h² + (D / 2)²)”, where C is the length of the lateral component of the cone, h is the required height, D is the diameter. Carefully fold the finished cut out scan with a cone (Fig. 3)

- Racks for connecting parts into a single structure are made from the same sheet metal. (Fig. 4) The length of the posts is determined by the dimensions of the structure, taking into account the required margin from below (approximately 20 mm for 1-2 rivets for attaching to the glass). It is better to place these elements at an angle to the vertical - from the pipe to the edges of the umbrella.

Now about assembly. We attach racks for 1-2 rivets to the “glass” pipe. We insert the mesh cylinder into the space between the racks-holders so that it enters the lower pipe a little and rests on the cone. Now we expose the fungus - we bend the mounting pads of the racks so that they fit snugly against the inside of the cone. We drill through holes through the racks and umbrella, after which we finally fix the entire structure.

Size calculation

Before starting work, you need to measure the dimensions of the chimney, in accordance with which the sketches of the device will be displayed.

It is important to pay special attention to the diameter of the plug - the cross section should be slightly larger than the diameter of the chimney.

It is equally important to determine the correct size of the cells - they should not be more than 5 mm.

Installation video

Mounting Features

Proper installation depends on the dimensions of the device parts. At the slightest discrepancy between the diameters, it will not work to install a spark arrester on the pipe. A welding machine is used to connect individual elements. The joints obtained after welding must be thoroughly cleaned. For final fixing, you will need rivets or brackets.

Common errors and installation problems

Often, the master neglects the conformity of dimensions, which does not allow later to securely fix the device. Another common mistake is the selection of too narrow cells for the strainer. In this case, traction is disturbed, and the element itself is very quickly clogged with soot.

Many do not know that it is strictly forbidden to weld the installation to the chimney tightly.

Maintenance and care

The complexity of maintenance depends on the selected device model. In general, for all options, the competent operation of such a device comes down to periodic cleaning of the grid from soot.

If we are talking about a deflector with a "skirt", you will have to periodically check that insects, leaves and other small debris do not block the holes to remove rain and melted snow.

Distance from chimney to spark arrester

The mounting height of the cone must be within the minimum allowable values so that the structure does not disturb the draft and at the same time does not allow debris and precipitation to enter the pipeline from the outside. To calculate the required parameters, we recommend using the following table:

| D,mm (chimney diameter) | W, mm (visor width) | H,mm (height to chimney) |

| 120 | 240 | 144 |

| 140 | 280 | 168 |

| 200 | 400 | 240 |

| 400 | 800 | 480 |

| 500 | 1000 | 600 |

Conclusion

In the absence of a spark quencher, the likelihood of ignition of debris accumulating on the roof increases significantly. To prevent possible fires, it is definitely worth installing such a device. Moreover, the cost of most models does not bite, and if desired, its simplest version can be made independently.

If you thoroughly comply with all norms and requirements, including those of a fire-fighting nature, then any spark that inadvertently flew out of the chimney is guaranteed to go out until it reaches the building next to the bathhouse. But there are two buts. Firstly, no one observes building codes in our country in principle, and secondly, the bath's own roof can be made of materials capable of igniting. In general, to be sure to avoid trouble, it is worth installing a spark arrester on the chimney. We read the article.

Any fuel combustion is associated with the release of thermal energy and combustion products, in which, in addition to volatile substances and gases, there may be small fuel particles entrained by the outgoing jet, and in which combustion processes of varying degrees of intensity continue. In principle, active sparking can be caused by several reasons:

- Direct-flow type chimney with a short vertical arm. Naturally, the greater the length of the smoke channels, the more tortuous their path, the more likely it is that all the sparks will die out, somewhere else, in the first third of the smoke passage.

- Too much thrust, which causes intense combustion and a high speed of the outgoing flow, which will provoke the separation of small particles of burning fuel and their removal into the atmosphere.

- The use of fuel prone to increased sparking. Traditionally, well-dried coniferous firewood, especially spruce, is considered to be such. The provocation of sparking is ensured by the high and massive stacking of firewood in the furnace, when the lower logs burn out, the upper ones collapse with a characteristic emission of a whole sheaf of sparks. Whoever remembers the big pioneer bonfires will not let you lie.

Important! It should be remembered that, in addition to the primary sparking described above, there is a secondary one, in which soot deposits in the smoke channel ignite. They pose no less of a fire hazard to the surrounding buildings. That is why, in fact, timely should be given close attention.

In principle, the fight against soot, the use of fuel that is not prone to sparking, fine adjustment of the draft of the furnace can suppress sparking in the bud. However, it is impossible to fix a straight-through short chimney, then the spark arrester on the bath pipe becomes an indispensable accessory.

Brief overview of the design

The spark arrester for the chimney can be made in the form of:

- Perforated damper at the chimney section. This type is the simplest, if not primitive, solution to the spark suppression problem. A spark arrester for a bath pipe with your own hands can be quickly made by simply drilling holes in a metal plate, which is then fixed to the cut of the pipe. The efficiency of spark extinguishing will be very high, since the area of the holes will be much lower in relation to the area of the entire plate. Accordingly, the draft and the quality of smoke removal as a whole will deteriorate. In the near future, the problem will become even more aggravated, since the flow area of the holes will decrease due to the accumulation of soot directly on the plate, in the zone of flue gas outflow;

- Mesh cap, put on the pipe. In this variant of solving the problem, there are practically no obstacles to the free flow of smoke from the pipe, but the efficiency of such a design will be relatively low. With an abundant release of a sheaf of sparks, there is an objective probability that some of them will break through the mesh barrier without hindrance;

- Spark arrester for a bath in the form of a deflector. This construction works as follows. A blind plate is put on the mouth of the pipe, the plane of which is in some way curved outward. She herself rises on high legs at a level of approximately 150 - 270 mm from the chimney cut. Absolutely nothing interferes with the outflow of smoke, the sparks are extinguished due to the collision of the emitted sparks with a cold metal plate, as a result of which the spark instantly loses its temperature and changes its trajectory. Among other things, such a system protects the mouth of the pipe from the ingress of precipitation and foreign objects into it. At the same time, it should be noted that with strong crosswind gusts, sparks can be blown away before they come into contact with the deflector. It is obvious that in strong winds sparks quickly lose their temperature, but, nevertheless, the theoretical possibility of ignition exists;

- The most effective is the combined spark extinguishing system and only it can rightly be called a system. It consists of a blind deflector plate and a mesh frame of the space below it. The opening diameter of the mesh should be about 3.5 - 4 mm. The maximum allowable value should be considered as 5 mm. The sparks emerging from the pipe are mostly extinguished by contact with the plate and abruptly lose their dynamics, finally extinguishing occurs from contact with the mesh sidewall. It also prevents the phenomenon of sparking during gusts of side wind.

Attention! The material for the manufacture of a spark catcher system must meet several fundamental requirements: be non-combustible, have high resistance to adverse atmospheric phenomena, and have an attractive appearance. Almost all of these requirements are met by stainless steel.

Maintenance of spark detection systems

Like any, the simplest mechanism, a spark arrester needs routine maintenance, which are as follows:

- Inspection for the integrity of the entire structure. At least once a year.

- Cleaning of the main components and assemblies from soot and other deposits. Twice a year.

- Unscheduled inspection and cleaning. For example, in areas with an abundance of common poplar, the fluff of this tree is able to clog the spark arrestor grid to the state of a dense fiber. In addition to worsening traction, such a nozzle is also a fire hazard. It is necessary to carry out such work as an objective need arises and there are no specific deadlines.

By the way! Maintenance and repair of spark arresters are classified as high-altitude, so their implementation must be ensured by strict observance of the rules and safety requirements.

Ferrous metal systems under conditions of different temperature loads and condensate formation are prone to increased corrosion, which predetermines closer service attention to them than in relation to systems made of stainless steel.

Independent production of such a product

Making a spark arrester for a bath with your own hands is not difficult. It is enough to know the basic rules for the ratio of the deflector diameter to the diameter of the chimney cut. For clarity, we present this data in the form of a table:

| Chimney pipe diameter at the chimney cut, mm | Deflector diameter, mm | Height from pipe cut to deflector sole, mm |

| 80 | 160 | 150 |

| 100 | 200 | 150 |

| 110 | 220 | 150 |

| 140 | 280 | 150 |

| 150 | 300 | 150 |

| 180 | 360 | 200 |

| 200 | 400 | 200 |

| 250 | 450 | 220 |

| 300 | 500 | 250 |

| 350 | 550 | 270 |

| 400 | 600 | 270 |

The following are suggested as "quick fixes" to the problem:

- The end of the metal pipe is closed with a blind cover, and vertical slots are made in the side walls in increments of 10 - 12 mm. Slot width 5 mm. It is convenient to arrange them with an angle grinder;

- As we said above, cover the mouth with a perforated plate;

- A cap made of fine mesh is put on the pipe, on which, for rigidity, rings made of steel strip are worn;

- The smoke exhaust system is equipped with a damper and a knee to reduce the speed and intensity of flue gas outflow. True, this option cannot be called fast, since it requires a direct reorganization of the smoke exhaust system.

It is possible to build a complete combined system of roofing galvanized sheet or stainless steel, 0.8 mm thick.

A word from Experienced! However, it should be remembered that for cutting galvanizing, as well as any other material that has a protective coating, you cannot use an abrasive tool. Only special cutting shears working on the principle of "matrix - punch". Otherwise, the cut points will begin to corrode intensively. In addition, galvanized and other coatings have little resistance to thermal effects.

Stainless steel is characterized by high strength and toughness, which requires the use of special methods and techniques for its machining.

As a rule, the elements of such products are fastened with rivets, the use of welding is possible only of a semi-automatic type using a shielding gas environment. In some cases, hard soldering is used. Both welding and soldering require equipment and solid practical skills.

Conclusion

A spark arrestor for a bath, in a number of cases, is a necessary element in equipping the furnace system of a home bath or sauna. According to a number of requirements of SNiP, namely, when using a roof made of bituminous material, and also if the furnace uses coal or coal briquette as fuel, equipping the pipe with it is a must. In most cases, we consider it useful to equip our bath with this simple device, then we can guarantee to remove many of the risks of using a sauna stove, in any weather and climatic conditions. All the same, it is worth playing it safe, because Moscow burned down many times, and we are talking about some kind of baths.

Wooden structures are at great risk, for the ignition of which one spark is enough. Therefore, chimneys are recommended to be equipped with a protective device - a spark arrester (spark catcher). This is a special nozzle on the pipe, equipped with a fine metal mesh under the "umbrella".

Design features and principle of operation

There are many types of spark extinguishers. They differ in external configuration, material of manufacture, dimensions. But their working principle is the same.

Spark arresters can consist of a single grid, they are cheaper than models with a deflector (chimney), they are easier to manufacture, but a device with an “umbrella” is more functional.

The shape and some features will be determined not only by your desire, but also by the shape of the pipe where the spark arrestor is planned to be installed.

Main structural elements:

- body ("glass"), which is mounted on the chimney;

- mesh cylinder (the main structural element);

- umbrella deflector.

How does the device work? The smoke exits through the chimney channels, colliding with an obstacle (“umbrella”), is forced to change the direction of movement, to pass through the metal mesh. If there are sparks in the combustion products, the mesh extinguishes them or “breaks” them into microscopic sparks that are not dangerous.

A spark arrester is a necessary element for straight chimneys with strong draft. Such protection will not be superfluous on a chimney of any design.

There are other reasons to install a spark arrester - it will prevent birds from getting into the smoke channel to make nests there, and also protect against other animals, debris, rain and snow.

Do-it-yourself spark extinguisher

A reliable spark arrestor for the chimney can be made independently. Let's get acquainted with the main stages of such work for a round chimney. We advise you to study the material about in more detail and find answers to your questions.

Required tools:

- saw blade or grinder;

- metal scissors;

- a hammer;

- welding or riveting;

- clamps.

A few important points

The mesh size should be 3-5 mm. Do not use too small cells, gases must pass unhindered.

Important: design flaw - periodically the mesh cylinder is clogged with soot and dust. This is unavoidable if firewood with a high resin concentration is used. The mesh must be cleaned regularly. This will avoid the effect of reverse thrust.

Be sure to sketch. To do this, make all the necessary measurements as accurately as possible. Pay special attention to this work. The sketch will help determine the required amount of material, the exact dimensions of the parts that you will need to make in order to assemble a high-quality and aesthetic design.

If you do not have experience in such work, make a full-size mock-up of the construction from thick cardboard. This will clarify all dimensions, and the parts of the layout will be excellent patterns when creating your spark arrester.

Prepare sheet steel, galvanized or stainless steel (thickness 0.6 - 1 mm). Determine the size of the sheet according to the dimensions of the sketch. You will also need a grid of stainless or galvanized wire with a mesh size of 3-5 mm.

mesh cylinder

From the mesh, carefully cut a piece of the required size with scissors. It will be a rectangle, the largest side of which should be equal to the circumference of the grid cylinder. On one of the sides it is necessary to add a mounting valve (width 15-20 mm) for riveting. With a cylinder height of up to 10 cm, 2-3 rivets are sufficient.

From the grid it is necessary to form a neat cylinder. To do this, you can use, for example, a pipe cut of a suitable radius.

Tip: the formation of a cylinder from the mesh can be facilitated by tapping it with a hammer. This operation will relieve stress from the metal, it will be easier to deform.

"Cup"

It's easy to cut it out. It is enough to know the height and circumference of the base. Please note that a mesh cylinder will be inserted into the "glass".

Umbrella deflector

Difficulty in the manufacture of a spark extinguisher can only be created by a cone-shaped "fungus" or "umbrella". The cone is formed from a circle, having previously cut out an angular segment. And here a school geometry course will come to your aid. If you have made a layout, then you already have a drawing of a cone, just cut it out of a sheet of steel, remembering to add a mounting valve. We have previously written about and recommended bookmarking the article.

Tip: to make it easier to get a neat cone, the workpiece can be “rolled” on a horizontally fixed pipe of small diameter.

Racks

Another important detail is the racks, which allow you to connect all the components into one structure. They can be made from metal rods, or they can be made from sheet steel. Stand width 15 mm. To increase strength, they are made three-layer. This must be taken into account when cutting a workpiece from steel.

The length of the workpiece will depend on the design features, but do not forget to provide for the possibility of fastening: on each side of the rack, reserve space for 1-2 rivets.

Tip: it is better to place the racks at an angle to the vertical (from the “glass” to the “umbrella”), this will make the structure stronger.

When all the parts are made, they begin to assemble the spark arrester.

- Racks are vertically attached to the pipe or "glass". For this operation, you will need 1 or 2 rivets.

- A mesh cylinder is inserted between the uprights. The cylinder should enter the "glass" with an emphasis on the rivet heads. It should be of such a height that, in a fully assembled structure, it rests against the cone of the "umbrella".

- If the racks are mounted vertically, then greater strength can be achieved by attaching a metal mesh to them. As fasteners, use 1 rivet for each rack.

- Set up an umbrella. The mounting sections of the racks are bent so that they fit snugly on the inside of the cone. Through holes are drilled, rivets are installed and finally fixed.

Installation completed. The device can be fixed on the pipe and no longer be afraid of sparks flying from the chimney.

When assembling, if possible, welding can be used instead of rivets. Welding joints must be cleaned with a grinder. We recommend to study for further self-production.

Tip: If your roofing material is flammable, attach a special metal plate around the chimney, on which sparks will fall that can pass through the mesh.

A spark arrester is a reliable protection for your home and your yard from fires. If desired, it can be turned into an interesting element of decor. For example, you can make a chimney in the same style as a weather vane, gutters and other metal elements of the facade.

Liked?

The owner, who is building a wooden house or a bathhouse on his site, will have to think not only about how to equip the future building comfortably. It is very important to ensure the comprehensive safety of the operation of this building. It is necessary to solve the issue of a well-thought-out fire safety system.

The heart of the modern sauna is the stove, which usually runs on solid fuel. It is necessary to ensure the correct installation of both the furnace structure itself and the smoke exhaust system in order to prevent the risk of poisoning with harmful gases and to exclude the possibility of igniting walls, ceilings, and roofs. And another important point - the chimney itself should not be a possible source of danger in the bath room. For these reasons, they install a spark arrester on the chimney, which you can buy or make yourself.

You should not convince yourself that this element is not so important, because in the event of a fire, you will not forgive yourself for this negligence. In addition, making your own spark arrester is not difficult.

Stainless steel chimney spark arrestor

Peculiarities

Any construction associated with the combustion of fuel and the removal of harmful products outside the heated premises poses a danger to buildings. Especially when the material of the dwelling is not resistant to fires (for example, wood).

Therefore, when building a house, it is necessary to comply with fire safety rules. This applies to both the stove and the boiler and the chimney, because together with the fuel processing process, combustion products are also emitted into the chimney. This process is usually not complete without sparks, and they, in turn, can cause a fire. In order to protect themselves and their own housing, they mount a special device - a spark arrester on the chimney.

The device catches sparks, being installed directly on the flue pipe. Its design includes a body, a grid for trapping and extinguishing sparks, an element for extinguishing fire and a visor.

By and large, a chimney spark arrester is a regular grid with small cells. The structure is elementary.

We can also highlight the following features of the device in question:

- These devices are installed on the chimney pipes of solid fuel stoves.

- The cells of the mesh itself must correspond to certain sizes, namely, be no more than 5 mm.

- Installation of a spark arrester is mandatory if the roof is made of materials that can easily ignite.

- Devices are required when the chimney is installed straight (in baths, saunas, etc.).

- In addition, the spark arrester protects the pipe from birds and debris.

- The grid needs to be cleaned from time to time.

- The installation of a spark arrestor mesh is included in the chimney project.

Please note that when heating the stove with wood with a high resin content, you will have to refuse. Otherwise, the resin that will settle on the grid will clog it, and the draft in the chimney will become less.

It is not difficult to make a spark arrestor for the chimney yourself, but you need to take a responsible approach to the choice of mesh material. Not all of them can be used, for example, when using ferritic steel or galvanized metal, this can contribute to the rapid wear of the device.

The installation of the spark arrester is carried out immediately after the installation of the chimney itself.

The best material for the mesh is stainless steel, 5 mm thick. Stainless steel devices have excellent properties of strength, resistance to corrosion, and are characterized by a high rate of thermal stability.

Varieties

Currently, there are a huge variety of spark arrestors that differ from each other in designs, but still two types are especially popular:

- spark arrester in the form of a stainless steel casing;

- products in the form of a deflector.

The main condition is unhindered traction in the structure. The gases must flow through the chimney easily and not meet barriers. In addition, the spark arrester must extinguish all sparks coming through the pipes.

The dimensions of these devices can be different, it all depends on the diameter of the chimney. The diameter of the spark catcher can be either 80 mm or 550 mm. The size of the visor directly depends on the diameter of the connecting pipe that is installed on the chimney. Review the table to understand the dependency.

| Connecting pipe DN, mv | Du of a peak, mm |

|---|---|

| 80 | 160 |

| 100 | 200 |

| 110 | 220 |

| 120 | 250 |

| 130 | 250 |

| 140 | 280 |

| 150 | 300 |

| 160 | 300 |

| 180 | 360 |

| 200 | 400 |

| 230 | 400 |

| 250 | 450 |

| 280 | 450 |

| 300 | 500 |

| 350 | 550 |

| 400 | 600 |

| 450 | 650 |

| 500 | 750 |

| 550 | 800 |

The spark arrester operates on the chimney for a bathhouse or at home is very simple. It is worth saying that completely all types of these products function in a similar way:

- Combustion products move through the flue duct.

- At the tip, they are prevented by a spark arrester, which changes the direction of movement along the axis.

- At the outlet of the pipe, sparks pass through a grid that extinguishes them.

The spark catcher may have a different shape, but the principle of operation will always be the same.

Making a spark arrester with your own hands

We have already figured out that the design of the spark arrester is simple, the device often looks like a cover that is put on the chimney.

Spark arrester in the form of a chimney cap

It is not difficult to buy a product, but it will be even easier and cheaper to make a spark arrester for a chimney with your own hands. This option is recommended for a short time, because it is not very convenient to use and has the following disadvantages:

- Dirt and soot quickly settle on the grid. This will eventually affect good draft and the removal of gases from the chimney.

- Incorrectly calculated distance between cells. This design does not hold sparks well, which can easily fly out of the pipe. At the same time, a mesh that is too small will cause clogging.

Spark arrester in the form of a pipe with holes

Another option that is not difficult to do yourself (in the image).

It looks like a pipe with drilled holes. You can buy it or make it yourself. Choose a pipe slightly larger than the chimney. Holes are drilled in it, an umbrella is fixed with reconciliation. Then all this product is attached to the chimney with rivets. This option looks pretty simple, but the problem lies in the number and size of holes. Incorrectly drilled holes can reduce traction. Therefore, if you make the design yourself, then carry out the necessary calculations or go empirically. Remember that the latter will require more time and effort.

Here is another photo of this product.

Mesh chimney spark arrester

In this case, it is necessary to responsibly approach the choice of grid size to eliminate problems similar to those in the model above. This product will also have to be removed and cleaned more than once, because the holes will become clogged with dirt.

If you don't want to bother with cleaning all the time, you can put a dome-shaped spark arrester. In it, the size of the grid cells is changed.

However, it does not exclude the problems associated with the ingress of dirt into the oven, because this model does not have an umbrella.

Popular models

Now consider more durable options. In the image - the best option in terms of functionality. It is inexpensive, and it is not difficult to do it yourself if you have the skills of a locksmith.

Chimney spark arrester with mesh and umbrella

The base is made of galvanized steel with a thickness of 0.6 to 1 mm. It is not necessary to choose a very thin one, although it is easier to work with it. We need reliability. The mesh can be welded from bars, but it is better to buy ready-made, made of stainless steel. The cost will not be much more expensive, but it will be much easier to work compared to bars. Take cells ranging in size from 3 to 5 mm. Carry a grinder, metal shears and a drill to make holes for fasteners. Due to the fact that the metal will have to be bent, you will have to prepare a workbench with a metal corner or part of a flat channel / corner.

Spark Arrestor Dimensions

Remember the need to comply with fire safety, especially if you have a wooden building that is heated with wood. The spark arrester is an important part of the smoke exhaust system, which will allow you not to worry about the occurrence of a fire when heating the stove.

It is easy to make a spark arrester for a bath pipe with your own hands, having a drawing, a metal mesh and sheet steel. The head is given the shape of a chimney: a circle or a rectangle. However, no spark arrester will help if it is wrong to heat the stove in the bath. Most models of caps protect only from a small amount of sparks flying out with smoke.

Sparks from the bath pipe: what to do

The spark arrestor does its job as long as the sauna chimney is functioning properly. Violation of the rate of smoke circulation leads to the fact that sparks begin to fly from under the cap. The first step is to figure out where they come from. Sparks are small particles of fuel that have not had time to burn in the furnace. With normal draft, they manage to burn out in the furnace, and some of them smolder inside the pipe on the way to the exit from the chimney.

With a decrease in smoke circulation, the fire in the furnace goes out. If the thrust is higher than normal, the opposite effect occurs. The fuel quickly flares up, crumbles into particles that do not all have time to burn. A strong draft of the air stream picks up these particles along with the smoke and throws them out through the pipe into the street in the form of a beam of sparks.

The problem of sparks is inherent in a direct-flow pipe, which is the only drawback of such a chimney design. The fire from the furnace immediately enters the vertical pipe. If the chimney channel of the bath has knees, bends, horizontal sections, the smoke circulation is weakened. Even with strong traction, the sparks hit the walls of the pipe at turns, scatter into smaller parts, and have time to burn out before departure. However, curvilinear chimneys quickly become clogged with soot. For a bath with knees, a pipe is not the best option.

The problem is solved by reducing the speed of the smoke circulation of the once-through pipe. Thrust is regulated by dampers, gates, blower door. If positive results cannot be achieved, the residence time of smoke with sparks in the pipe is increased by increasing the length of the chimney channel. After the thrust is normalized, rarely flying sparks are caught by the spark arrester.

Attention! You have to be careful with traction.

A decrease in smoke circulation below the norm leads to gas contamination of the bath with carbon monoxide, which is deadly to humans.

The structure and principle of operation of the spark arrester

The spark arrester device of different models has distinctive design elements. Appearance is different. Common is the presence of a housing, a spark-extinguishing element made of steel mesh or sheet, as well as a cover that delays the escape of sparks.

All models of spark arresters work on the same principle:

- After igniting the sauna stove, hot combustion products are formed inside the furnace, consisting of gas, smoke, air, and small particles of unburned fuel. The draft air flow directs them through the chimney of the bath to the street.

- At the top of the pipe, hot air collides with the tip. The smoke freely escapes into the atmosphere, and the particles of burning fuel hit the extinguishing element made of mesh or sheet metal, the housing, the deflector cover.

- A burning spark that hits a metal element loses its heat capacity and quickly dies out.

The spark arrester most often traps large fuel particles. Small sparks sometimes slip through. If sparks fly strongly from the bath pipe, it is necessary to reduce the draft by closing the dampers. Another reason may be the burning of the spark arresting grid.

Spark Arrestor Models

Models of spark arresters differ in design, method of trapping and extinguishing sparks, and auxiliary features. Conventionally, the elements are divided into the following groups:

- Dynamic models deposit burning particles by gravity. From contact with a cold deflector and a grid of heat-intensive metal, the spark loses energy.

- Filtration models extinguish sparks and purify gases passing through the cellular filter partitions. For a bath, such a spark arrester is rarely used. More often it is found on the exhaust pipe of a car, tractor, combine.

- Liquid seals- a special type of spark arresters. The combustion products pass through the water, where 100% of the sparks are extinguished, soot settles. Cold air without the smell of burning comes out of the chimney outside.

A dynamic model is most often put on the pipe. However, even such a bath head has different modifications.

The simplest in design is considered a model in the form of a casing. Its main task is to capture sparks. More from the casing should not expect anything. The deflector is more complicated. The spark arrester is equipped with an additional element for redirecting air flows. For some models, the weather vane rotates. In addition to extinguishing sparks, the deflector enhances the draft in the pipe.

How to make a spark arrester on a pipe in a bath

It is easier to bend a spark arrestor for a bath in the form of a casing from sheet metal and mesh. The design has no moving parts and is simply put on the pipe. A diagram with dimensions will help to correctly cut the fragments.

Choice of model and materials

When choosing a cap model for the chimney of a bath, you should once again carefully consider its effectiveness. A conventional casing is simple, but it only catches sparks and is not able to improve traction. It is better to equip the bath pipe with a deflector. Which option to choose is up to the owner of the bath to decide.

Before starting production, they buy the material. For any spark arrester you will need sheet steel. Galvanized will do, but stainless steel is better. Still need a grid with small cells.

From the tool for assembling a steel structure you will need:

- metal scissors;

- a hammer;

- electric drill;

- chisel;

- pliers;

- rivet gun.

In order not to be mistaken with the calculations, a prototype is first made from paper - an exact copy of the spark arrester. You will need the following materials and tools:

- thick elastic cardboard;

- stationery stapler;

- paper scissors;

- pencil;

- ruler;

- compass.

If the choice fell on a head with a deflector, in addition to the outer thickness of the chimney of the bath, measure the diameter of the pipe from the inside. On the sheet with the drawing put their dimensions.

They think in advance how to fix the steel elements of the spark arrester. Rivets are the best option. In the absence of a riveter, the fragments are connected by welding. The ability to weld thin metal is important here. If you burn a hole in the case, sparks will break out.

The efficiency and longevity of the spark arrester depends on the quality of the material. Sheet stainless steel and mesh are used with a thickness of about 1 mm. Thick metal is difficult to work with.

Advice! When accessing the rolling machine, the head can be made no worse than the store version, and stainless steel is suitable even with a thickness of 5 mm.

The mesh can be perforated sheet steel. In any embodiment, material with holes of 4-5 mm is suitable. Through large cells, sparks will freely break out. Small cells will clog faster, in addition, the draft through the pipe will worsen.

Making a prototype spark arrester

After removing the inner and outer diameters of the bath pipe, we proceed to the manufacture of a paper prototype. Drawing elements are transferred to cardboard. At the joints, an allowance of about 2 cm is left. The width of the seam should be enough for the hole for the rivet.

The lined fragments of the head are cut out of cardboard. It must be elastic, otherwise creases will appear when bent. Temporarily, the parts are connected with a clerical stapler. The finished prototype of the spark arrester should be life-size and put on the bath pipe.

If the template suits in all respects, it is dismantled. The paper clips are carefully unfolded at the joints, removed, the fragments of the head are straightened, laid on a stainless steel, outlined with a marker. A marking pencil is not suitable, as it is hard to see on steel.

Do-it-yourself product assembly

After transferring the individual parts of the cardboard prototype of the spark arrester, the fragments are cut out of metal. Usually it is an umbrella, strips of different sizes, a rectangle from a grid for a cylinder. The body of the spark arrester, with which it will be mounted on the chimney, is easier to cut off from the finished pipe. However, a suitable stainless steel workpiece with the desired diameter is difficult to find. The pipe is bent independently from a rectangular sheet of steel, the joints are connected with rivets.

Further work is based on the assembly of all elements into a single structure. If, instead of a riveter, docking is performed by welding, the width of the allowance is made less than 2 cm. Welds are cultivated by grinding with a grinder.

The sequence and specifics of assembling a homemade spark arrester for a bath depends on the model. The usual model casing is assembled without gaps. Sparks flying out of the bath pipe should hit obstacles on their way. In the second option, a deflector is first made. A skirt is formed from a sheet of stainless steel. The detail resembles a saucer with curved edges. Holes are drilled on the lower part of the upper glass of the spark arrester and the skirt is fixed with rivets.

If the manufacture of a spark arrester turned out to be difficult, there is an option to improve the bath pipe. The method depends on the material of the chimney. The metal pipe of the bath is closed from above with a plug. The upper part, about 20 cm wide, is perforated with a 5 mm drill. If the bath pipe is brick, it is simply covered with a mesh on top. The spark arrester turns out to be primitive, but it will delay some of the flying sparks.

Installing and fixing the device

When the spark arrester is ready, it remains to climb onto the roof of the bath and install it. The head is put on the pipe. To prevent it from being blown away by the wind, fixation is carried out. To the round pipe of the bath, the lower part of the head is pressed with a clamp. The method is reliable and convenient. The clamp is always easy to release to remove the spark arrestor for cleaning.

For fixing to a rectangular pipe, a home-made rim with brackets is used. Another fixation option involves the use of rivets. The head is held securely on the pipe. However, if maintenance is necessary, the rivet will have to be cut off with a grinder, which is extremely inconvenient. The last option is to weld the spark arrester to the metal pipe of the bath. The idea is bad. For maintenance, you will have to cut off the head from the pipe with a grinder each time.

More information on making a deflector for a bath pipe can be found in the video:

Conclusion

Do-it-yourself spark arrester on the bath pipe, if desired, can be assembled in a couple of hours. It is important to have a drawing with exact dimensions, quality material and the right tool.

New Articles

- Russian-Portuguese phrasebook for tourists (travelers) with pronunciation

- Portuguese for tourists

- What are the main differences between Spanish in Spain and Latin America?

- Danish-Russian online translators Danish language translator

- What is the difference between Portuguese and Spanish

- Transiting Saturn Opposition Natal Saturn Moon-Saturn Opposition in Radix Male

- Horoscope of work and money

- Protection from the evil eye and envy will help save what is expensive. How to put protection from

- What does it mean if you have a dream within a dream?

- Chinese horoscope Ox (Ox)

Popular Articles

- Herbal teas for sore throat

- What to do with diarrhea and temperature in an adult

- Fortune telling on wax: the correct interpretation of the figures The procedure for conducting fortune telling

- Moon Pisces Compatibility Who suits a woman with the moon in Pisces

- What does a Scorpio love about sex?

- I dreamed of a neighbor descending from the stepladder along the vanga

- Short Course in Theoretical Mechanics

- Preparation for the exam in mathematics (profile level): tasks, solutions and explanations

- Sophia-Assumption Cathedral in Tobolsk

- The Poltava diocese confirmed its loyalty to the canonical Ukrainian Orthodox Church